|

|

|

|

|

|

|

|

| The

following tools

are required

to service your

calipers: |

- One

1/4 inch

twelve point

socket

-

One ten

millimeter

twelve point

socket

-

One 1 inch

socket wrench

-

One flat

head screwdriver

-

One phillips

screwdriver

-

One spray

can high

quality

brake cleaner

-

One torque

wrench

- One

Pair Lyndall

Z-Plus pads

- One

bottle of

Harley-Davidson

brake fluid

|

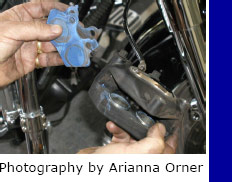

| There

are two bolts

holding each

caliper on Harley-Davidson

motorcycles.

There are also

two pins that

hold the pads

in place. If

your motorcycle

has two front

calipers, please

start by removing

the caliper

furthest away

from the master

cylinder, which

on most Harley-Davidson

motorcycles

is the one on

the left side

of the motorcycle,

or in other

words on the

side of the

clutch lever. |

| The

first step is

to loosen the

two pins that

hold the pads

in place with

the one inch

twelve point

socket. Once

this has been

accomplished,

remove the two

bolts that secure

the caliper

to the front

forks with your

ten millimeter

twelve point

socket. |

| The

caliper can

then be gently

removed from

the rear of

the motorcycle. |

| Once

the caliper

has been removed,

turn the caliper

over so that

you can se the

condition of

the pads. Leave

the pads secured

within the caliper

and have someone

else assisting

you to pull

on the front

brake level.

As they do,

notice how the

pistons in the

calipers are

moving as hydraulic

fluid will move

initially while

the pistons

that are furthest

away from the

source of hydraulic

pressure will

in all probability

hardly move

at all. |

|

|

|

|

|

|

|

|

|

|

| This

is due to a number of

factors. First, all of

the pistons in a Harley

Davidson caliper are virtually

the same size. The further

the piston is away from

the source of hydraulic

pressure the more pressure

it requires to move at

the same rate as the pistons

that are closer to the

source. The only way that

this can be accomplished

where both pistons front

and rear move at the same

rate is with differential

bore, meaning that the

pistons furthest away

from the source are smaller

in diameter so that less

hydraulic pressure is

required to move as freely

as the pistons that are

nearest to the source

of hydraulic pressure. |

| The

other problem that causes

pistons to drag and hang-up

is that since there are

no dust boots on the pistons,

brake dust and general

road dirt accumulates

around the pistons. Once

the brake cleaner spray

has successfully removed

all of the debris, take

your flat headed screw

driver and place the blade

in between the old pads

and force the pistons

back into the caliper.

Have you assistant pull

on the brake lever once

again and repeat the process

as described above until

all four pistons move

relatively freely. |

| Once

you are satisfied in their

performance, remove the

two pins that secure the

pads in place with the

one inch twelve point

socket. Once the pins

have been removed, gently

remove the pads that were

secured within the caliper.

Take notice of how the

pads were installed since

they are different in

configuration. Install

the two new pads. Once

in place, re-insert the

two pieces and loosely

tighten until the caliper

has been re-installed

on the rotor. |

| Gently

spread the two pads apart

with your fingers until

there is sufficient space

between the two pads to

allow you to re-install

the caliper on the rotor.

Once the caliper has been

successfully re-installed

place a few drops of Blue-Locktite

(242) on each bolt and

tighten each bolt between

28-38 pounds of torque.

Once they have been tightened

install the 1/4 inch twelve

point socket and tighten

the two lock pins that

hold the pads in place. |

| After

you have successfully

accomplished all of what

has been outlined above,

top off the master cylinder

if necessary by removing

the master cylinder cover

with a Phillips screw

driver and replacing it

when finished. Pump the

brake lever until all

of the air has been removed

from the system. I have

found that after pulling

on the lever a number

of times if you flick

the lever a number of

times you will notice

that there will be little

movement in the lever

before full pressure can

be applied to the pistons. |

| If

you are interested in

maintaining maximum braking

performance as well as

brake longevity it is

recommended that you follow

the above cleaning procedure

every 2,500 miles. If

you prefer having others

service your motorcycle,

please consider giving

them a copy of this document

and have them perform

this process for you. |

|

|

|

| |

|

|

TO

ORDER

YOUR REPLACEMENT

LRB

Z-PLUS PADS,

PLEASE

CALL

(800)

400-9490

OR

VISIT OUR WEBSITE:

www.lyndallracingbrakes.com

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|