|

|

|

|

|

- Baggers

Magazine - May, '08

- American

Iron Retailer - March-April,

'08 - Product Review

- American

Iron Retailer - March-April,

'08 - Showcase

- Drag

Specialties –

Magazine, Nov/Dec ‘07

- AMD

- August, '07 - Out

Braking the Competition

- Speed

- July, '07 - Tech Feature

- American

Bagger - August, '07

- Tech

- Barnett's

- July, '07

- V-Twin

- August, '07

- HOT

ROD's Bike Works, February,

'07

- HOT

BIKE - JULY, '06

- V-TWIN

- JUNE, '06

- THUNDER

PRESS - JUNE, '06

- THUNDER

PRESS - OCT, '05

- EASY

RIDERS MAGAZINE - OCT,

'04

|

|

| |

American

Iron Retailer - March-April,

'08 >

Product Review

|

Brake

Pads And Calipers

Lyndall

Racing Brakes And Hawg

Halters Inc.

800.400.9490

www.lyndallracingbrakes.com

Over

The Counter

By: Paul Kittrell

and Mark Thompson |

| |

(Download

the article in PDF format

here.)

(Click

here

to read the American Iron

Retailer "Showcase")

|

|

THERE

HAVE BEEN A number

of new developments in braking

systems over the past several

years. We spoke with Paul

Kittrell, founder and president

of Lyndall Racing Brakes,

and Mark Thompson, owner

of Hawg Halters Inc. to

find out which brake pads

and calipers are best suited

for each application, and

how to best sell these braking

solutions. — MK

|

Lyndall

Racing Brakes

Lyndall Racing Brakes has

been in business for 10

years. I started the business

in 1998 with a solidbackground

in premium friction materials

from my sevenyear tenure

at Porterfield Enterprises,

the largest supplier of

friction material for racecar

applications on the West

Coast. As a club-level motorcycle

racer, I was unimpressed

with what was available

in the market for motorcycle

brakes. So, in my spare

time, I began hand-cutting

brake pads, from the same

premium friction materials

used in racecars, for AMA

superbike racers. The racetrack

was the testing ground and

theater of validation for

Lyndall’s products.

One year later, in 1999,

production of brake pads

for Harley-Davidson motorcycles

began. We have since expanded

our products to fit all

American cruiser applications

as well as many others. |

|

Because

Lyndall has chosen to focus

on the Vtwin market segment,

our production runs are

typically smaller than other

brake-pad manufacturers

who typically merchandise

mass-produced brake pads

for everything with wheels.

This allows greater quality

control and more focused

research and development

of our products. This boutique

business concept also allows

the company to provide superior

customer service, as Lyndall

is committed to 100-percent

customer satisfaction, going

so far as to offer a money-back

guarantee on all our products,

unlike any other brake-pad

manufacturer. |

| |

Brakes

Are Not Created

Equal

Lyndall has found

that one of the

best ways to discern

high-quality brake

pads from others

on the market, independently

and without bias,

is by logging onto

some of the motorcycle

forums on the Internet

to get the facts

straight from the

riders themselves.

A forum provides

feedback from a

wide crosssection

of riders from all

around the world.

Everyone loves to

express his opinion,

and the Internet

is one place to

do that freely.

So you’ll

find straightforward

talk about products

— no holds

barred. Short of

your own independent

research, the old

adage stands true:

you get what you

pay for. Premium

components don’t

come cheap, but

they can save much

time and aggravation.

Fix it right the

first time, and

you’ll earn

your customer’s

loyalty, possibly

for life.

Since

not all brake pads

are created equal,

some technical information

can help you understand

the differencesbetween

the kinds available

on the market. There

are three types

of friction material

commonly used for

motorcycle brakes:

sintered metal,

ceramic, and Carbon-Kevlar.

Sintered-metallic

brake pads, which

have a high metal

content, are typically

hard and abrasive

to the rotor surface

while offering moderate

stopping power and

mechanical strength.

Service life tends

to be |

|

significantly lower,

and sintered-metallic

pads tend to run

more dirty and noisy

than other types

of friction material.

They are also inexpensive

to manufacture and

are the cheapest

pads on the market.

Ceramic

brake pads usually

have a high copper

content and are

sintered as well.

While ceramic pads

generally offer

a slightly longer

service life and

run cleaner than

sintered-metallic

pads, they

offer only moderate

stopping power.

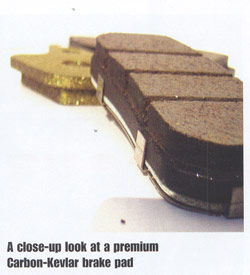

Carbon-Kevlar pads,

often referred to

as organic pads,

usually have a small

percentage of iron

or nonferrous metal

and are softer than

other friction materials.

Carbon-Kevlar pads

typically run clean

and quiet, and offer

good stopping

power. They have

an extremely long

service life and

are not abrasive

to the rotor because

they generate less

heat than other

friction materials.

Lyndall’s

brake pads are of

the Carbon-Kevlar

variety. What makes

Lyndall’s

pads unique is that

they contain a premium

blend of Carbon-Kevlar

and nonferrous metal

and have a high

transfer rate. Once

the pad material

has transferred

a layer to the rotor,

the rotor effectively

becomes one big

brake pad, stopping

against the two

smaller brake pads

positioned in the

caliper. The result:

incredible stopping

power, no dust,

no noise, no drag,

no measurable rotor

wear, and the highest

service life of

any pad on the market.

Finding out which

brake pads work

with a particular

caliper can be a

challenge, but most

manufacturers (Lyndall

included) list application

information, complete

with OE part numbers

crossreferenced,

on their web sites.

Also, a phone call

to a rep for those

hard-toidentify

pads can help provide

an answer. By looking

at your sales andservice

history, you can

also identify which

models are the most

popular in your

dealership. Those

would be the best

ones to keep in

stock. Keep in mind

that the older-model

bikes are a diminishing

market segment,

so it’s best

to limit your stock

to one or two of

each fitment.

Safety,

Service, And Sales

As

a safety precaution,

shop owners and

their technicians

should always look

at brake pads whenever

a bike comes into

the shop for any

type of service

or repair work.

While brakes are

a known safety item,

premium-quality

brake pads are also

a great customer

service item that

can enhance the

pleasure of your

customer’s

riding experience.

Installing a brake

pad that solves

the rider’s

dust or noise problems

can boost confidence

in your service

department and increase

repeat business.

The brake pad is

just one component

of an entire braking

system. This system

needs regular check-ups

and maintenance.

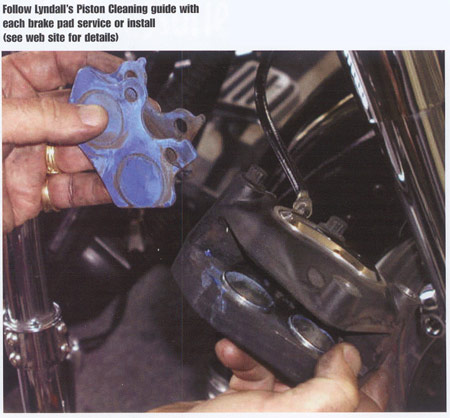

Lyndall recommends

cleaning the pistons

located in the caliper

with every brake

pad service. A step-by-step

guide to this process

can be found on

the Service/Tech

page of our web

site. You may also

request a brochure

detailing the process

directly from the

company. Steel-braided

brake lines and

high-performance

brake pads and calipers

are the best upgrades

you can make to

a brake system.

Remember also that

without good tires,

premium brakes cannot

be nearly as effective.

Be sure to check

tire pressure regularly,

but not until the

tires reach optimal

operating temperature;

about 30 minutes

into a ride.

Brake

pads should be displayed

in a manner that

is inviting to the

customer. When shopping

for anything, brakes

included, tactile

sense is important.

People like to touch,

pick up, and examine

when making a choice.

Nine times out of

10, if a customer

picks up the part

he’s considering

and holds it in

his hand, he’ll

buy it. Product

displays should

be accompanied by

informational brochures

and pamphlets for

the customer to

review while waiting

or to take with

him to consider

for a later purchase.

Banners and posters

explaining the products

can also create

excitement and stir

curiosity. Potential

margins for selling

Lyndall’s

pads range from

30 percent to 40

percent. Remember

that the more profitable

you are, the better

customer service

you’ll be

able to provide,

and the happier

your customers will

be.

Hawg

Halters Inc.

Hawg

Halters Inc., also

known as HHI, started

up in 1999 to meet

the customer desire

for improved braking

performance over

the stock H-D product,

and to provide a

custom-styled product

adaptable for a

variety of applications.

HHI has dedicated

itself to supplying

the aftermarket

with a top-quality

brake caliper that

performs well and

has a smooth, clean,

custom appearance,

all at an affordable

price. We also specialize

in braking systems,

so we have the widest

array of products

to fit most any

application. |

What

Calipers To

Choose?

To

effectively

sell a product

to the customer,

application

information

is critical.

The dealer

needs to identify

the specific

make/model/year

for proper

fitment. Dealers

also need

to understand

what the customer

expectations

are. Price,

performance,

and appearance

are all equally

important.

Most

dealers are

aware of the

low cost import

products now

available.

If you’re

not sure,

always ask

the supplier

or manufacturer.

HHI brake

calipers are

designed and

manufactured

in our plant

using only

USA-made materials

and components.

|

|

|

This

provides us with

complete accountability

and support for

our products. Knowing

that these products

are made in the

USA is a strong

selling point dealers

can use in making

the sale.

Caliper

differences are

mainly found in

materials and design.

Stock calipers are

generally made of

cast aluminum that

has a lower tensile

strength as compared

to billet aluminum.

HHI manufactures

all its calipers

from 6061-T6 billet

aluminum allowing

it to design a lighter,

stronger caliper.

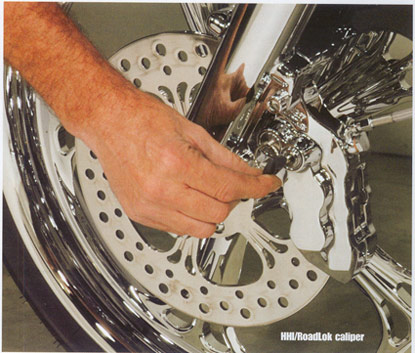

A

recent offering

from HHI now integrates

braking with security.

The idea of attaching

a lock to the rotor

has been around

along time, but

integrating that

feature into the

caliper is a revolutionary

concept produced

by RoadLok. This

new product provides

braking and security

in one package,

which makes locking

the bike more convenient

and safer while

providing braking

improvement at the

same time.

Our

newest braking-product

line is a six-piston

caliper designed

specifically for

use with our new

13" floating

rotors. This is

also a great upgrade

over stock, especially

with the introduction

of the new braking

system using a 11.8"

rotor on the 2008

H-D touring models.

We’ve mainly

sold these as dual-to-single

disc conversions

on baggers when

installing custom

wheels.

Upgrading

to an HHI four-

or six-piston caliper

should be done on

any bike still equipped

with the 1999-and-earlier

single-piston unit.

If it came as a

stock single disc,

then a single replacement

will provide plenty

of i m p rovement

and the same goes

for the dual-disc

upgrade. Bikes from

2000 and later are

equipped with the

H-D four- piston

caliper. Customers

looking for a chrome

upgrade, and who

are satisfied with

perf o rmance, could

be sold the four-

piston version;

however, the six-piston

will give them a

performance improvement

over stock. Touring

model bikes equipped

with dual discs

will also find good

perf o rmance with

the HHI four- piston

upgrade and a significant

improvement when

switching to six-piston

calipers.

Fitments

and Upgrades

Most

distributors and

brake-pad manufacturers

have a catalog cross-

reference listing

the various fitments

for most stock and

aftermarket calipers.

If unsure, the dealer

should contact the

manufacturer for

specific fitments

as there are a wide

variety of pads

available.

Dealers

should stock the

most common bike-model

fitments, which

include left- and

right-hand front

fourpiston calipers

for both 1999-and-earlier

and 2000-andlater

versions. The HHI

‘99-earlier

caliper can also

be used for rear

applications when

assembled with HHI

rear brackets. Caliper

installations should

always be accompanied

by a brake fluid

flush service. Periodic

caliper cleaning

while installed

on the bike can

be helpful in clearing

brake dust and debris.

Most HHI calipers

feature dual seals,

one of which is

a dust seal that

helps extend the

life of the main

pressure seal.

Calipers

are best shown in

a display cabinet

or installed on

a shop bike. Promotional

literature supplied

by the m a n u f

a c t u rer and

displayed with the

calipers is an effective

way to promote the

product and educate

customers. Typical

margins for the

dealer are 25-30

percent. Brake caliper

sales can often

be coupled with

other components

such as brake rotors

and brakeline replacements.

AIR

|

| |

|

|

|

|

|

|

|

|

|

| |

|

| |

|