|

|

|

|

|

- Baggers

Magazine - May, '08

- American

Iron Retailer - March-April,

'08 - Product Review

- American

Iron Retailer - March-April,

'08 - Showcase

- Drag

Specialties –

Magazine, Nov/Dec ‘07

- AMD

- August, '07 - Out

Braking the Competition

- Speed

- July, '07 - Tech Feature

- American

Bagger - August, '07

- Tech

- Barnett's

- July, '07

- V-Twin

- August, '07

- HOT

ROD's Bike Works, February,

'07

- HOT

BIKE - JULY, '06

- V-TWIN

- JUNE, '06

- THUNDER

PRESS - JUNE, '06

- THUNDER

PRESS - OCT, '05

- EASY

RIDERS MAGAZINE - OCT,

'04

|

|

| |

Barnett's

- July, '07> Product

Review

|

Metal

Matrix Composite Rotors

Lyndall

Racing Brakes LLC

800.400.9490

www.lyndallracingbrakes.com

By

Mark Barnett

Photography: Frank

Rangel |

| |

|

|

| So

another racing company trying

to muscle in on the Harley

crowd, eh? Well you better

be able to chrome it you

say. Now just hold on there,

let’s let this guy

give his schpiel and then

we’ll bolt them on

and try them, you can decide

then. Paul Kittrell working

out of Santa Ana, California

is offering metal composite

brake rotors and custom

pads to bolt right onto

your standard Harley models.

The rotors are light, a

little under two pounds

each with their aluminum

carriers and titanium buttons.

Stock rotors weight 4.7

lbs each, so you are removing

about 2.8 lbs of sprung

weight from each wheel if

you have a single disc set

up like the 2006 Harley-Davidson

FLST shown here. Just this

weight reduction I the wheel

area gives better steering,

better feeling over rough

roads and better braking.

Then comes Lyndall Racing’s

race-proven rotor design.

Made out of a metal matrix

of impregnated metal, it

offers, according to the

manufacturer, unparalleled

braking performance when

paired with their pads. |

| Lyndall

is not oblivious to the

Harley riders’ concern

with looks and also offers

pads to work with stock

Harley rotors plus their

own line of highly polished

stainless steel rotors for

those who need some flash.

If you choose to go with

the best stopping power

like we did, you order the

metal matrix discs. You

do get to pick the cut and

finish of the disc carriers.

You can look at all the

available designs and colors

at www.lyndallracingbrakes.com.

|

|

| When

we got our discs in, the

lightness was very impressive,

but the proof was to be

in the stopping so we headed

out onto the greasy streets

of El Paso on the windiest

day of the year. Real world

testing on crappy roads

in dusty conditions. Admittedly,

I was starting to have second

thoughts, as it was my bike

the front and rear discs

were mounted on and any

slide outs or front end

tucks/bike dumping would

immediately result in a

new article, “How

to install new fenders and

a tank on a Harley Softail.”

Don’t laugh, this

was almost the case. I did

about six runs at 30 mph

and seven or eight at 50

mph for each set up, stock

and Lyndall, measuring all

the stopping distances.

I had three front end tucks

which resulted in the bars

turning left and quick aborts

on the runs. I was on the

brakes to point of locking

both the front and rear

each time. You could definitely

smell the rubber. I took

the best three stops for

the stock set up and for

the Lyndall Racing set up. |

| |

| The

results were pretty

impressive, almost

a 20% reduction in

stopping distance

at both 30 mph and

50 mph. That translates

to an 18 foot shorter

stopping distance

at 50mph, one full

car length. This was

due simply to materials

of the rotors and

pads. They worked

as advertised: light

weight with improved

friction. There were

no noises or any other

problems with the

Lyndall Racing Units.

And as an old ex-racer,

I liked the racy looks,

gave the bike a touch

of seriousness in

my opinion. High technology

and safety doesn’t

always come cheaply,

each rotor is $549

and a set of pads

is $59. But if you

are planning to build

in performance to

your custom ride,

don’t forget

the brakes. Nowadays

with distracted drivers,

that 18 feet could

come in super handy. |

|

|

|

| |

V-Twin

- August, '07> Product Review

|

Metal

Composite Rotors: The

New Lite- Weight

Lyndall

Racing Brakes LLC

800.400.9490

www.lyndallracingbrakes.com

By

John Sullivan

Photography: John

Sullivan |

| |

|

|

There

was a time when using metal

to make something implied added

weight. With modern

technology, there are metal

composites these days that weight

next to nothing.

When

thinking about rotating motorcycle

wheels, lightweight is good.

So, along comes Lyndall Racing

Brakes with rotors made out

of the latest metal composites.

They are actually made from

two kinds of metal: the outer

disc is a metal composite; and

the inner hub is aircraft-grade

aluminum. The formulation that

is used for the friction disc

not only weights less, but it

dissipates heat better and resists

warping. The composite disc

is secured to the hub with aluminum

buttons that allow it to float

from side to side. The complete

rotor is less than half the

weight of a stock stainless

steel rotor.

Our starting point:

a 2006 Dyna Street Bob.

It has factory floating

rotors which weight

a couple of pounds each.

|

|

|

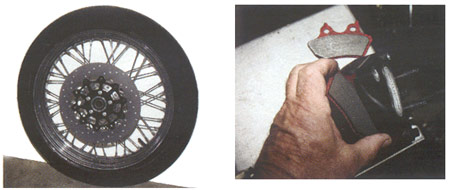

Lyndall

Racing Brakes Metal

Composite Rotors &

pads

|

LRB

offers 11½-inch rotors

for most 1984-up Harleys. For

our 2006 Street Bob we went

with rotors that had the hubs

finished in a black powder coating.

We also installed a set of their

Gold-series brake pads. The

installation was a straight

parts swap; everything fit like

the factory parts. The finished

biked stopped with two fingers

on the brake lever and looked

great doing it.

|

| We

attached the

LRB composite

rotor using

the factory

Torx bolts,

putting some

No. 271 high-strength,

red Loc-Tite

on the threads. |

The

LRB Gold series

brakes pads

fit the stock

caliper. These

have a metallic

friction material.

They will also

work with factory

stainless steel

rotors. |

|

|

|

| Here

we see the finished installation.

The rotor's hub complements

the spoked wheel. |

|

|

|

|

|

|

|

|

| |

|

| |

|